Some experts are cautiously optimistic about UniSieve’s technology, as it could potentially offer a cost-effective way to reduce pollution from industries like plastic manufacturing. If the tech can be successfully commercialized, it could have a significant impact on reducing carbon emissions and improving air quality in cities around the world.

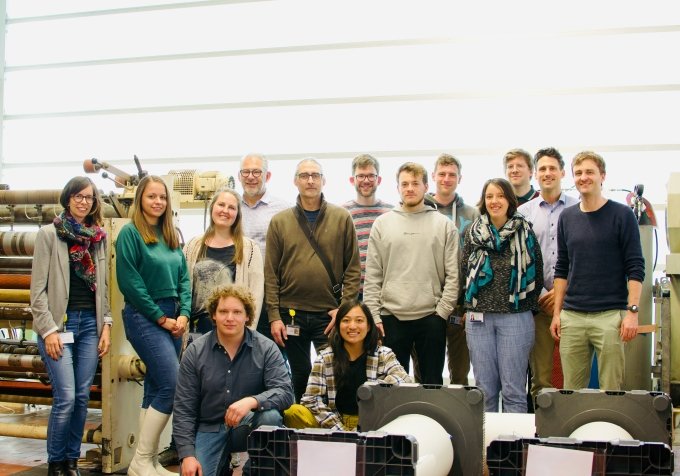

The startup’s new funding will be directed towards expanding the company’s operational capacities, including the launch of a new products and services offering. UniSieve CEO Lukas Linder said that the funds will also help to accelerate innovation within the company.

UniSieve is a Swiss start-up that was founded in 2018 by ETH Zürich classmates Samuel Hess and Elia Schneider. Their invention is a filter that uses porous crystals called zeolitic materials to achieve high-precision filters. These filters can be used in things like water filtration, gas separation, and drug purification.

Looking to make manufacturing more scalable and profitable, UniSieve has come up with a novel technology that can Capture CO2 emissions from large industrial plants. Their technology is already in use by several clients, including chemical and energy companies, and they are currently piloting hydrocarbon (organic compounds made of hydrogen and carbon) separation applications. This innovative company is sure to revolutionize the way we think about manufacturing, making it more affordable and environmentally friendly while still providing high quality products.

A UniSieve filter is capable of retaining smaller particles than traditional industrial filters, which could allow for a more efficient separation process. In addition, the modular design of the filters means that they can be easily integrated into existing systems, potentially saving businesses billions of dollars in savings and energy costs.

UniSieve’s membrane cartridges are an ideal way to catch dust, pollen, and other allergens. The cartridges make it easy to remove all of the allergens

Unlike thermal separations methods which use energy to break down the molecules of a gas, UniSieve uses size exclusion. Membranes made of polymer materials are placed over the gas inlet and the outlet, trapping smaller molecules while letting larger ones pass through. This process is repeated until all contaminants have been separated from the flue gas.

Zeolites have a great ability to adsorb and separate many different types of particles, making them a great choice for water filtration and gas absorption. By integrating zeolites into polymeric membranes, we can create much more effective filters that are also resistant to wear and tear.

The success of water purification membranes owes much to the work of Hess and Schneider, who introduced porous crystals into polymeric membranes in the early 1950s. These materials have since become essential components of advanced membrane technologies, and their versatility has made them vital for a variety of applications. Zeolites offer a unique set of Filterability Excellent Selectivity Capabilities Membrane Stability pore structure that can trap or filter specific molecules or ions efficiently – leading to better purification performance for separations such as gases.

UniSieve is a unified database system designed to process and analyze large amounts of data. It is capable

One challenge that UniSieve faced was its filters had to be extremely accurate in order to separate different gases. By precisely tuning the filter, UniSieve can be adapted for a variety of applications, including separating other gases besides CO2.

UniSieve is a new technology that effectively cleans hazardous or harmful compounds from liquids. Compared to other technologies like distillation or amine scrubbing, UniSieve’s membrane solution is up to 90% more energy efficient and can be applied at small, as well as large scale. This will make it easier for companies to clean their products safely and efficiently, saving both money and resources.

According to Lukas Weder, the UniSieve technology solution is ideally positioned to help companies quickly over to build very powerful energy efficient production processes. By automating and streamlining the card sorting process, UniSieve can significantly reduce the time and resources required to create efficient manufacturing processes. This would undoubtedly benefit both businesses and environmental sustainability in general- making it a valuable tool for any commercial or industrial enterprise.