Unfortunately, for those with dreams of living on the Moon or Mars, the task of finding a place to call home is proving to be a difficult one. However, there is a glimmer of hope on the horizon, as NASA has recently unveiled a self-assembling robotic structure that may play a major role in extraterrestrial colonization.

Published today in Science Robotics, the research from NASA Ames Research Center introduces “self-reprogrammable mechanical metamaterials,” a phrase that describes their revolutionary self-building structure.

“We believe this construction technology has the potential to be utilized in a wide range of applications,” says lead author Christine Gregg. “In the near future, the autonomous and lightweight design of our approach will greatly benefit tasks in harsh environments, such as the lunar surface or outer space. This includes constructing communication towers and shelters on the lunar surface before astronaut arrival, as well as creating booms and antennas in orbit.”

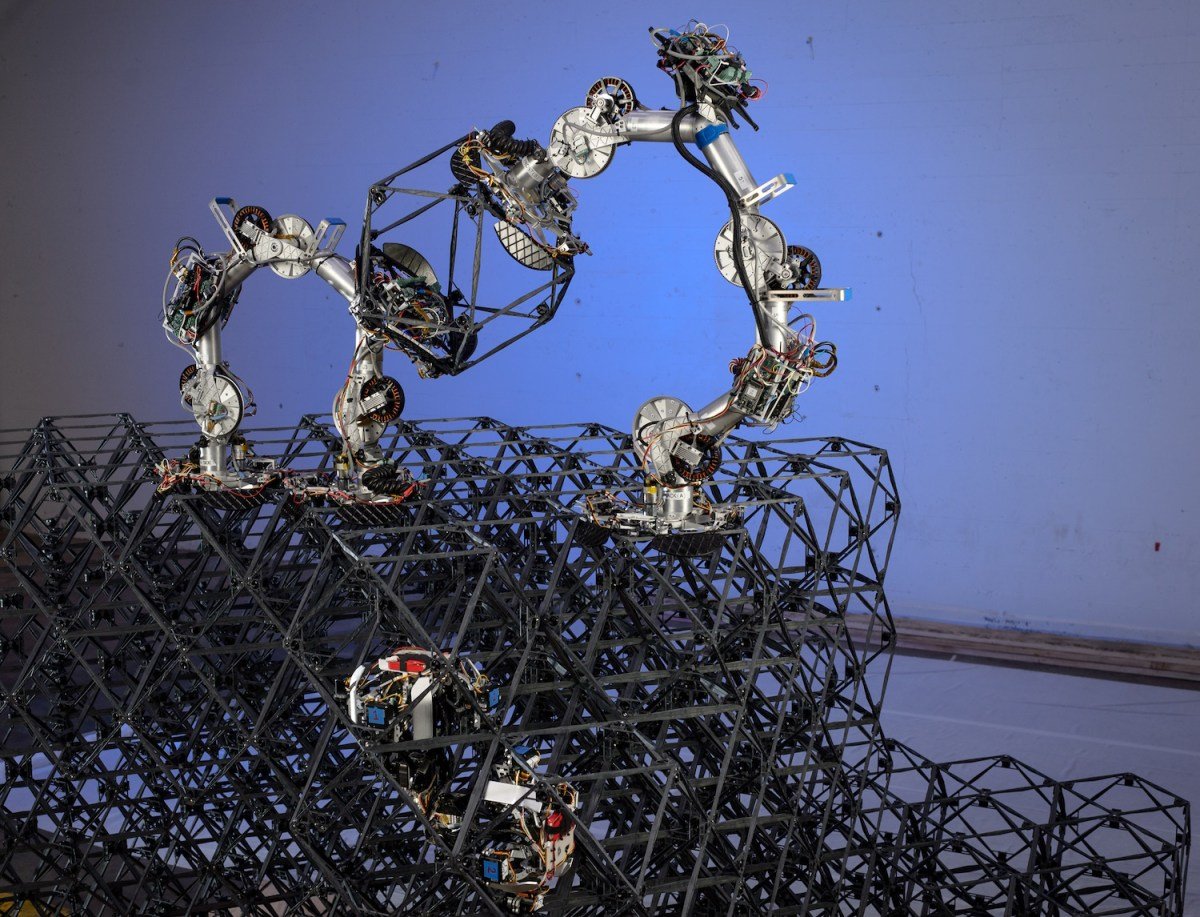

The concept behind the self-building structure relies on a clever harmony between the building material, known as cuboctahedral frames or “voxels,” and the two types of robots that construct them.

One type of robot, resembling human biology’s kinesin transport molecules, moves along the surface using its two legs to carry a voxel as if it were a backpack. Once in place, a worm-like fastening robot residing within the frame slithers over and secures the reversible attachment points. Neither of these robots require sophisticated sensory systems and their method of operation does not demand extreme precision.

The images surrounding this article depict the pair of walkers and fastener worm in action. One particular photo captures the handoff of a voxel from a transport walker to a placement walker, with the fastener bot awaiting its turn to lock the frame into place.

Due to the shape of the building material, it is possible to attach the voxels at various angles while maintaining a sturdy structure. While it may not be suitable for storing heavy objects, these frames serve as perfect bases for insulation and sealing to create a dwelling.

“We believe this type of construction is ideal for long-term or extensive infrastructure, such as habitats, instrumentation, or any other structures in orbit or on the surface of the Moon. This includes utility towers and vehicle landing facilities,” explains co-author Kenneth Cheung. “For us, the structures and robotic systems are highly adaptable resources that can be optimized over time and space. There will always be situations where the most efficient solution is to leave a structure in place and periodically inspect it using a robot. Therefore, we began with this concept in mind.”

In addition, the building material can be created on the location itself, as Gregg mentions:

“The voxels can be produced using various materials and manufacturing techniques. In the case of space applications, we plan to utilize materials found naturally on the Moon or other celestial bodies.”

Naturally, the videos of the robots at work have been sped up for viewing purposes. However, when it comes to constructing structures in space or on other planets, speed does not hold the same level of importance as it would in a factory or on a sidewalk.

“Our robots can operate much faster than what is shown in this article; however, it is not essential for achieving our primary goals. Essentially, the key to increasing the speed of this system is by incorporating more robots,” explains Cheung. “Our strategy for scalability (speed, size) is to delegate the complexity of scale onto algorithms, which includes planning, scheduling, detecting faults, and making repairs.”

In their lab, the robots successfully assembled 256 voxels into a shelter structure over the course of 4.2 days. Below is a glimpse of the beginning stages of construction (again, not in real-time):

If deployed to Mars or the Moon a year prior to a crew’s arrival, they could build twice the amount of structures, each being twice the size, with plenty of time to spare. Alternatively, they could add necessary plating to the exterior and seal it off, but this aspect has yet to be explored thoroughly.

Although the robots in the lab have attached power lines, the team is designing them with battery operation or on-site power in mind. The fastener bot is already equipped with a battery and the researchers are exploring ways to keep the walkers charged before and during operations.

“We envision robots being autonomously charged at power stations or possibly receiving wireless power,” adds Gregg. “As you mentioned, power could also be routed through the structure itself, which could be useful in outfitting the structure and powering the robots.”

The lab has already sent variations of these robots into space and conducted experiments in microgravity, posing no complications. There are no foreseeable obstacles stopping them from functioning in non-Earth gravitational fields, such as the Moon’s. However, this discovery is only the beginning, equivalent to uncovering the existence of 2x4s and nails.

“The following versions of our lab’s robots will feature faster and more reliable designs, based on the lessons we have learned with the initial versions. We aim to explore how different building blocks can be integrated into the structures to provide functional elements,” shares Gregg.

The team will also continue researching structures constructed by swarms of robots, not just a handful; a basic shelter as seen in this article may require two walkers four days to complete, but when the structure is ten times bigger, the duration may multiply by one hundred. However, as the saying goes, many hands make light work, especially when those hands belong to robots.