When Dusty’s FieldPrinter first entered the world of construction automation in 2019, it changed the game with its clever capabilities. This autonomous mobile robot was designed to bring blueprints to life by drawing chalk outlines on the site’s floors. This eliminated much of the guesswork and uncertainty typically associated with construction jobs. And with over 91 million square feet printed by the first-generation ‘bot, it’s clear that its impact has been significant.

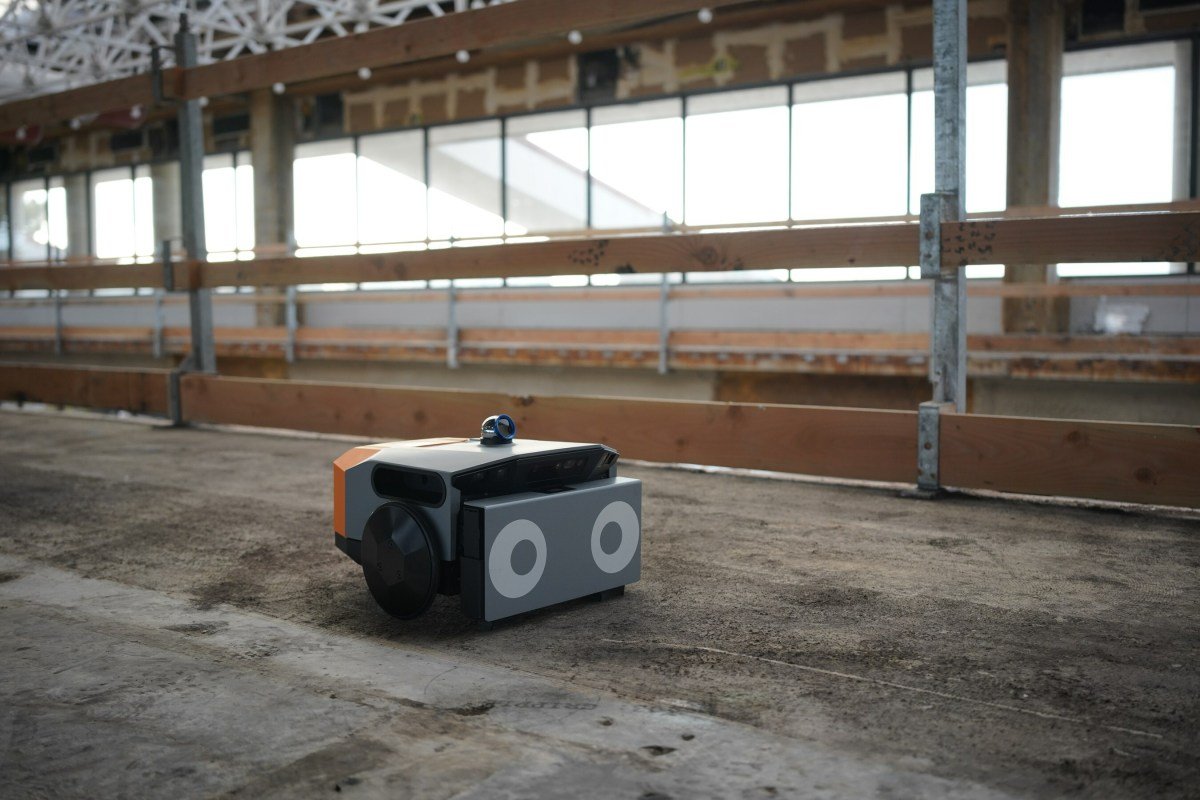

But now, the Bay Area-based startup is back with its highly anticipated sequel. And just like its predecessor, FieldPrinter 2 comes equipped with a pair of friendly, expressive eyes. This personification has proven to be surprisingly effective in integrating automation into the workplace. This new robot is even smaller than the first generation, allowing it to navigate around obstacles with greater ease.

One of the major improvements in FieldPrinter 2 is its ability to print closer to edges and even “shadow print” behind columns. Weighing in at just 23 pounds, this little robot also boasts a wider print head and a variety of on-board sensors for improved navigation. And with the added convenience of being able to control it via iPad, FieldPrinter 2 is a powerful tool for any construction site.

But that’s not all – alongside the launch of FieldPrinter 2, Dusty is also introducing its new FieldPrint Platform. This platform centers around BIM-to-field technology, which essentially brings digital information directly to real-world construction sites.

“Our new FieldPrint Platform supports the seamless flow of data from the design phase, to the field, and back to the trailer,” explains Tessa Lau, cofounder and CEO. “More than just a robot, Dusty provides an integrated software+hardware solution that architects, designers, and field operators utilize to get unparalleled accuracy, communication, and efficiency.”

The potential for robotics in the construction industry is immense, with this $2 trillion market in the U.S. alone. And in a time when there is a shortage of workers, automation is becoming increasingly important. This is why Dusty’s innovative solution is gaining competition, such as HP’s SitePrint.

In the end, it’s clear that Dusty’s FieldPrinter and its latest version, FieldPrinter 2, are paving the way for a more efficient and effective future of construction. With its unique technology and integrated platform, Dusty is bringing digital and real-world elements together like never before. And with the capabilities of this robot growing, the possibilities are endless.