Kombucha, a popular fermented tea among hipsters, has taken on a new role as a potential disruptor in the industrial world. At the 4YFN conference in MWC, we had the pleasure of speaking with Laura Freixas about her PhD research project that utilizes kombucha to transform organic waste into biodegradable filaments. This innovative process involves upcycling waste into threads that can be used to create various fabrics with unique properties.

Freixas, a member of the Elisava Research team at the Barcelona School of Design and Engineering, is hoping to commercialize this new type of filament called Biocel. “Our goal is to create filaments from organic waste, as we have identified many challenges in the textile industry,” she explained during our conversation.

While there have been recent efforts to develop eco-friendly leathers using biomaterials from fungi-based startups like Bolt Threads, Mycel, and MycoWorks, Freixas believes that not enough attention has been given to finding more sustainable alternatives for fabric production. The textile industry is known for its heavy use of harsh chemicals, energy, and water, leading to pollution and waste, as well as human rights violations due to poor working conditions.

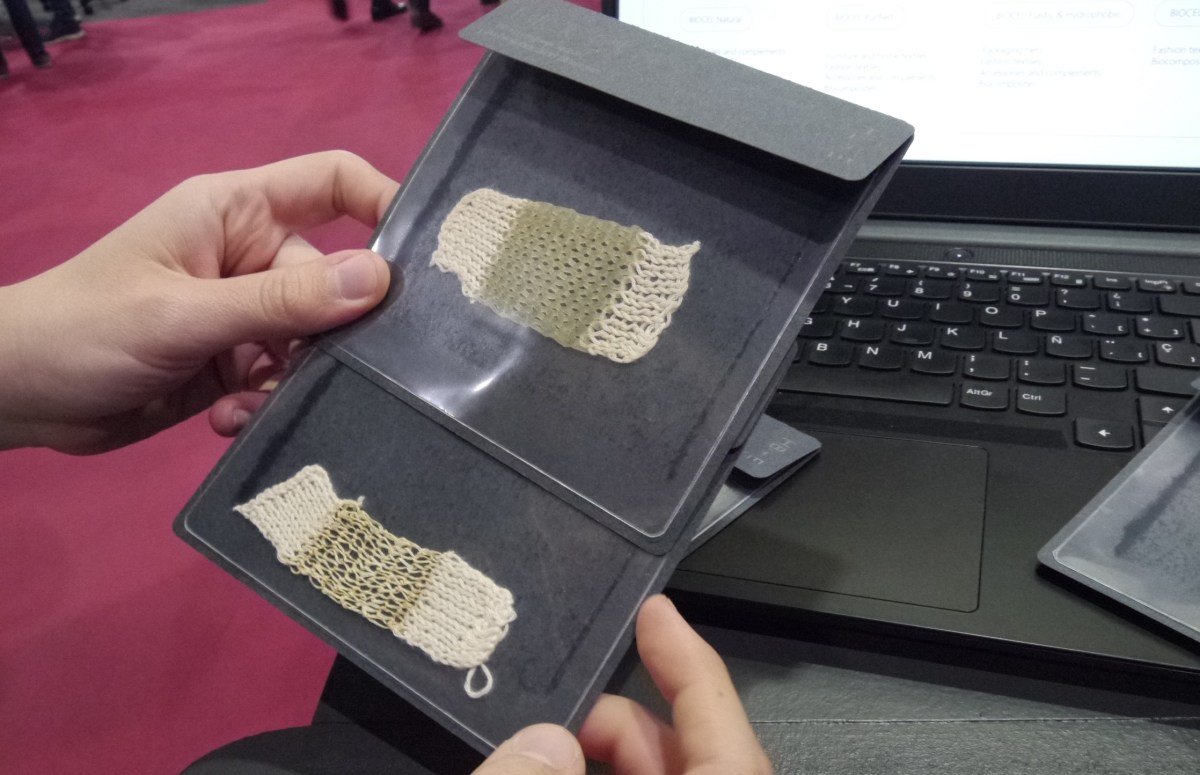

In contrast to traditional fabric production methods, producing Biocel is less labor-intensive and requires minimal energy and no hazardous chemicals, according to Freixas. “We use low levels of thermal energy and electricity to obtain a biodegradable filament that can be functionalized to have elastic, rigid, or hydrophobic properties for textile applications,” she shared with TechCrunch.

Similar to making kombucha, the feedstock for creating the bio-filament needs to have some sugar for the bacteria to ferment. This means that agricultural waste rich in sugar, such as grape waste from wine production or leftover cereals from brewing beer, is most suitable for the process.

Freixas pointed out that between 15% and 50% of agricultural products become waste during processing, presenting a significant opportunity for upcycling. As regulatory requirements in the European Union promote circularity and aim to reduce carbon emissions, Freixas predicts that industrial producers may even pay upcyclers to take their waste off their hands.

“We are currently working on building a digital platform to monitor and control the production of the bio-filament, as well as developing a patented method to ensure proper tension of the filaments,” Freixas explained. Looking towards the future, she envisions countless applications for the bio-filament, such as weaving it into accessories for the fashion industry, creating biodegradable packaging materials, or using it to produce textiles for furniture.

One limitation of the bio-filament at its current stage is its rough texture, making it unsuitable for fabrics that will be in direct contact with the skin. However, Freixas believes that further research can help refine the finish as they continue experimenting with various treatments.

“At this point, we are searching for a company with a real need for our filament. Together, we can develop an application, validate it, and then scale it for the market,” she added.

Wow, awesome blog structure! How long have you

ever been blogging for? you made blogging look easy.

The overall look of your website is excellent, as well as the content!

You can see similar: sklep

and here sklep internetowy