Faced with a shortage of labor, industries like manufacturing and agriculture are turning to AI for automation.

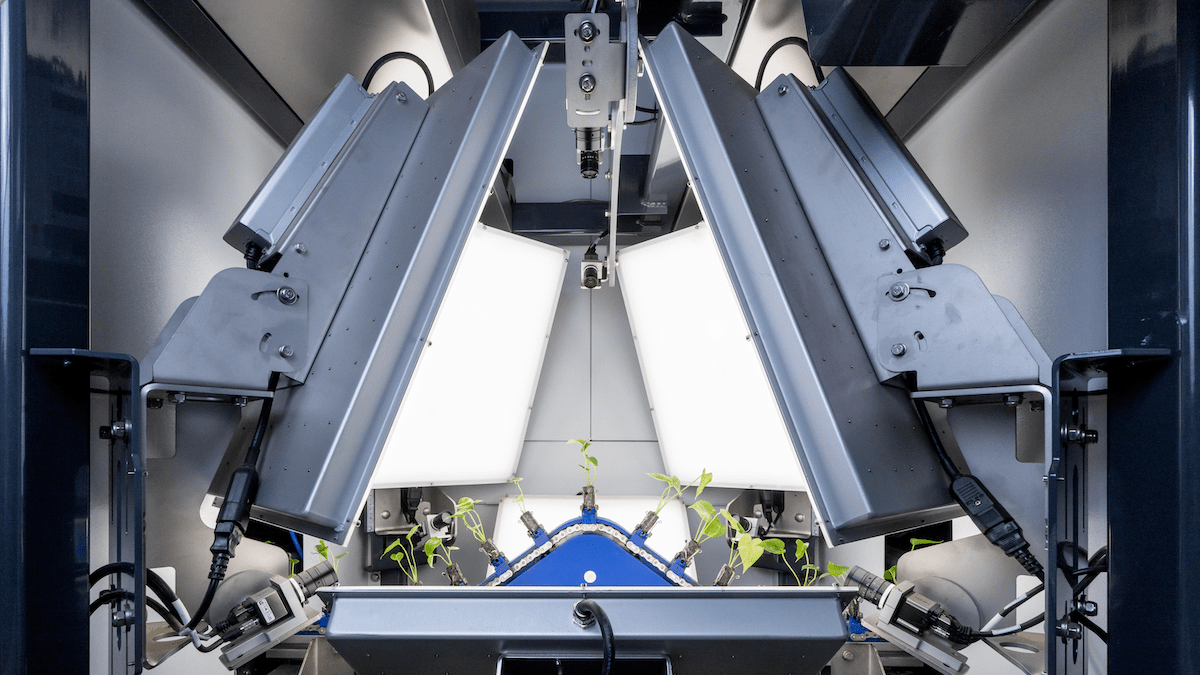

Computer vision startups are taking advantage of this opportunity, offering solutions for data collection, crop monitoring, and even harvesting with robots equipped with visual capabilities.

But there is a major challenge that must be addressed in order for these AI solutions to be effective: implementation. If they are not user-friendly, they won’t be utilized.

Belgian startup Robovision believes they have found a solution. They aim to industrialize deep learning tools and make them accessible to businesses that are not inherently tech-based. Their “no-code” computer vision AI platform eliminates the need for software developers or data scientists at every step. While they do not develop robots themselves, they cater to robotics companies looking to integrate AI-enabled automation in their machines.

Through Robovision’s platform, customers can easily upload data, label it, test their model, and deploy it for production. The company boasts a wide range of use cases, from recognizing produce in supermarkets to identifying faults in electrical components, to even cutting rose stems.

Already serving clients in 45 countries, Robovision’s CEO Thomas Van den Driessche shared in an interview with TechCrunch that they are now expanding to the United States, thanks to a recent $42 million Series A round. This funding is co-led by Belgian agtech investor Astanor Ventures and Berlin-based investor Target Global.

The choice to invest in Robovision is a strategic one, targeting the huge markets of industrial and agribusiness in the US. With a post-money valuation of $180 million, Robovision’s total equity funding is now $65 million.

But why is all of this important?

One of the challenges facing Robovision in its expansion is how to communicate and market their services to varied sectors. However, they have found that insights and experiments in one application can be applied to others. In fact, Robovision was able to apply their 3D deep learning technology for disease detection in tulips to diagnosing lung diseases in humans during the Covid pandemic.

Founder Jonathan Berte explains, “It has been the DNA of Robovision to find a balance between diversity and focus.” This is rooted in the company’s history, having started as a consultancy studio in 2012 before pivoting to their current B2B platform approach.

Initially gaining traction in the agtech industry, which now makes up 50% of their activities, Van den Driessche notes that other sectors are growing at a faster rate. While agtech remains a significant opportunity due to labor shortages and their track record of successfully helping ISO Group plant a billion tulips annually, other verticals such as life sciences and technology are seeing strong traction as well. For instance, Hitachi is utilizing Robovision’s platform for semiconductor wafer production.

Bao-Y Van Cong, partner at Target Global, shares his prediction: “I think [agriculture] is going to be industrial manufacturing’s largest sector.” He references Apple’s recent acquisition of AI startup DarwinAI, which specializes in overseeing component manufacturing, as evidence of the growing interest in this field.

For Berte, this is also an indication that a versatile toolbox that can support a variety of industrialized applications is crucial. He believes that, “Apple would never [have bought that] company if it were only a point solution.”

The capital Robovision needed for expansion was not easily secured from local investors, and the company had to look beyond Belgium and the Netherlands for funding. They were able to secure the necessary amount through a convertible note funding in 2022 and 2023, and this round would have required more dilution or been difficult to secure in the Benelux region.

Robovision’s Belgian roots have also played a role in their success. “The whole early team was very smart people from Ghent University,” Berte shares. While Van den Driessche became CEO in 2022, Berte focused on fundraising, partnerships, and global expansion.

Their growth has also led to the evolution of their technology, with the company rethinking the architecture of their computer vision tools in response to customer demand. This led to the launch of Robovision Edge, which caters to applications with low latency and delivery speed requirements.

In today’s market, innovation and productivity are key to global success. “I think the only way to do that is to innovate and become more productive,” Van Cong concludes.