The rise of humanoid robots in recent years has captured the attention of many, but at this year’s Modex conference, one particular robot stood out among the rest: Agility’s Digit. While it may be common to see a multitude of robotic humanoids wandering the halls of the Georgia World Congress Center in the future, for now, Digit stands alone as a testament to the company’s early success over its competitors such as Figure, Tesla, 1X, and Apptronik.

Last year, at Modex in Chicago, Digit made a significant impression as it showcased its abilities in industrial automation. Visitors were able to witness the bipedal robots efficiently moving totes to a conveyor belt during select times throughout the expo.

Fast forward to this year’s Modex in Atlanta, and a team of eight Digits captivate the audience as they demonstrate lineside replenishment and tote retrieval with a custom-made flow rack designed for the automotive manufacturing sector. Although Agility has yet to publicly reveal the names of its automotive clients, it has confirmed that it is currently working with them.

Agility’s first big break came when Ford announced a partnership with the company at the 2020 Consumer Electronics Show. However, plans to use Digit for last-mile deliveries were put on hold as the company shifted its focus towards addressing the immediate needs of warehouses and factories struggling with labor shortages, a challenge intensified by the COVID-19 pandemic. According to former Agility CEO Damion Shelton, last-mile delivery is still a possibility, but there is more than enough work to be done in the warehouse and manufacturing industries to keep the company busy.

In the past twelve months, Agility has made significant progress in terms of its management team. Founders Shelton and Jonathan Hurst have taken on new roles as President and Chief Robotics Officer, respectively, while former Magic Leap CEO Peggy Johnson has been appointed as the new Chief Executive Officer. Additionally, the company has brought Fetch founder and CEO Melonee Wise on board as its new CTO, and Aindrea Campbell, a former executive at Apple and Ford, as COO. These leadership changes not only show a company taking commercialization seriously but also puts Agility in a unique position among other top robotics companies with women holding five out of its nine C-suite positions.

With a focus on increasing production, Agility plans to produce a high double-digit number of its bipedal robots by the end of this year. At Modex, the company unveiled Agility Arc, a new software that allows for deployment and management of Digit’s fleet.

“The automation platform includes all the necessary features for fleet management such as battery and charging management, workflow management, and task allocation for the robots,” says Melonee Wise. “But it also encompasses other crucial aspects needed for configuring and supporting the system remotely. It’s a unified system that enables you to handle all aspects related to managing a fleet of Digits.”

According to Johnson, who previously led Magic Leap’s move into the enterprise sector, the new enterprise software gives her confidence in the company’s standing as a more robust and stable organization compared to her previous employer.

“When I learned about the new cloud automation system, I was highly encouraged. It is a clear sign of the company’s maturity,” Johnson states. “This is not just a device; it is a system intended for integration. At Microsoft, where I used to work, this was often a stumbling block. There, isolated systems hindered integration with other components, thus preventing them from reaching their full potential. Integration with WMS systems and other existing technologies is a huge advantage of this solution.”

For Johnson, Modex has been a learning experience, and she continues to immerse herself in the supply chain and logistics world. Last week, she even participated in the Tokyo marathon in Japan and returned over the weekend just to see firsthand the environment in which her company’s robots operate.

“I wanted to make sure I was here to see not only the customers, but also the working conditions,” Johnson explains. “Today, I will be spending time walking around and getting a feel for it all.”

Johnson’s primary focus as CEO is to deliver a fast return on investment for Agility’s customers. Thanks to the Robotics-as-a-Service (RaaS) model, companies can now test out Digit’s capabilities without worrying about high initial costs.

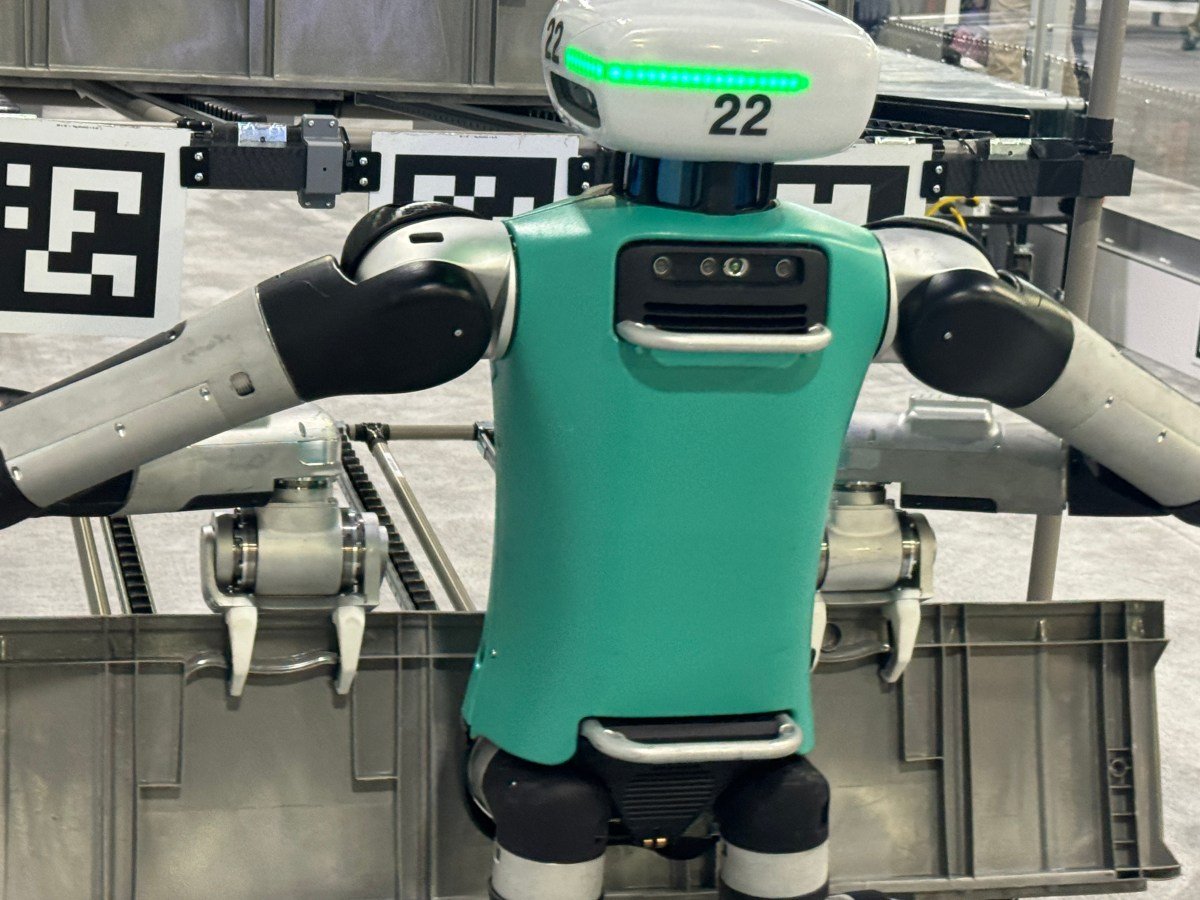

It is the customers who ultimately hold the key to Digit’s future. At Modex, a new version of Digit is being showcased, equipped with an alternative end effector. Instead of the flipper-style arms seen before, these Digits are equipped with four fingers on each hand, with two pairs of hooked fingers facing in opposite directions. However, this is not for intricate manipulation tasks but instead to perform the same function that Digit has been designed for – moving totes.

Interestingly, the totes used in the automotive workflow demonstration are significantly wider, prohibiting the robot from gripping them from both sides. Instead, the end effectors grasp the front of the totes, offering a more secure grip for transporting heavy and potentially unstable objects inside. In the future, Wise envisions a version of Digit that can swap out its end effectors as needed.

“There has been a lot of research and development on end effectors for decades,” Wise notes. “If you look around at Modex, you will see that all the robotic arms have different end effectors. This is a well-established practice, and it is even possible to automate the process of swapping out end effectors. This is something we are working towards as a product.”

Shelton adds, “Interestingly, none of the solutions on the floor today feature a five-fingered hand with 27 degrees of freedom.” He continues, “Some of our competitors have even admitted that their use of a five-fingered hand is merely for branding purposes.”

When it comes to competing with other companies, Wise believes that the focus should be on safety, a vital aspect of introducing new technologies in a warehouse setting. “As an industry, we need to agree upon safety standards,” she states. “We need to collaborate and determine what those standards should be.”

Johnson adds that companies should also stay focused on addressing current challenges and proving their technologies. “While having a roadmap is important, it is crucial to focus on what can be done right now,” she advises. “Keep your focus and prove yourselves.”